What This Guide Does

This guide helps operations managers, fleet managers, and facilities directors assess whether their current fuel purchasing method aligns with their operational requirements. It provides a structured evaluation framework—not a sales pitch.

Who This Is For

- Operations managing equipment or fleets where fuel interruption creates measurable cost

- Facilities with backup generators or critical heating systems

- Construction sites with mobile equipment requiring on-site fueling

- Organizations evaluating fuel supply as operational risk vs. commodity purchase

Who This Is Not For

- Residential fuel buyers

- Operations with no sensitivity to fuel supply timing

- Single-vehicle or minimal consumption scenarios

Two Fuel Purchasing Models

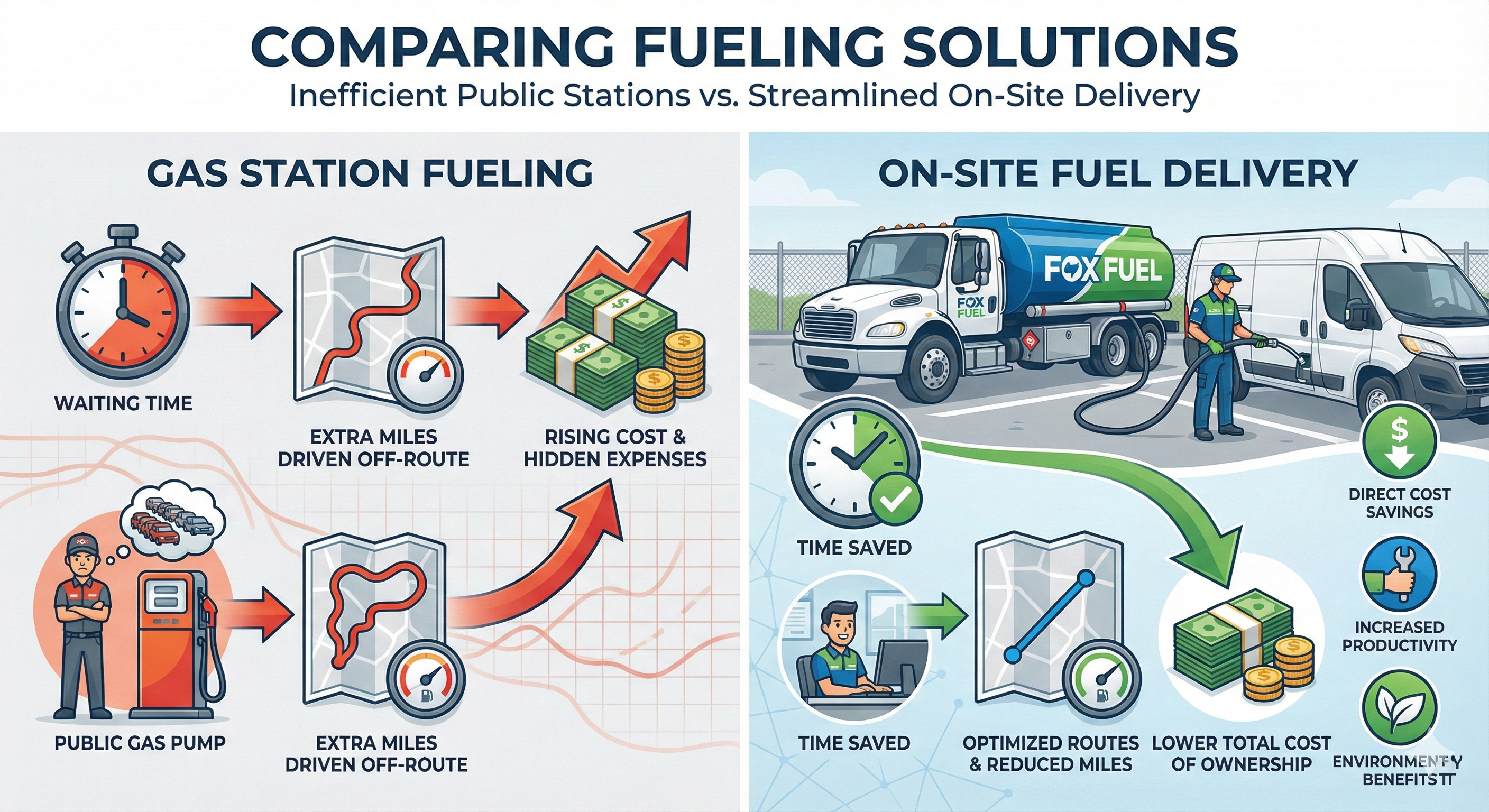

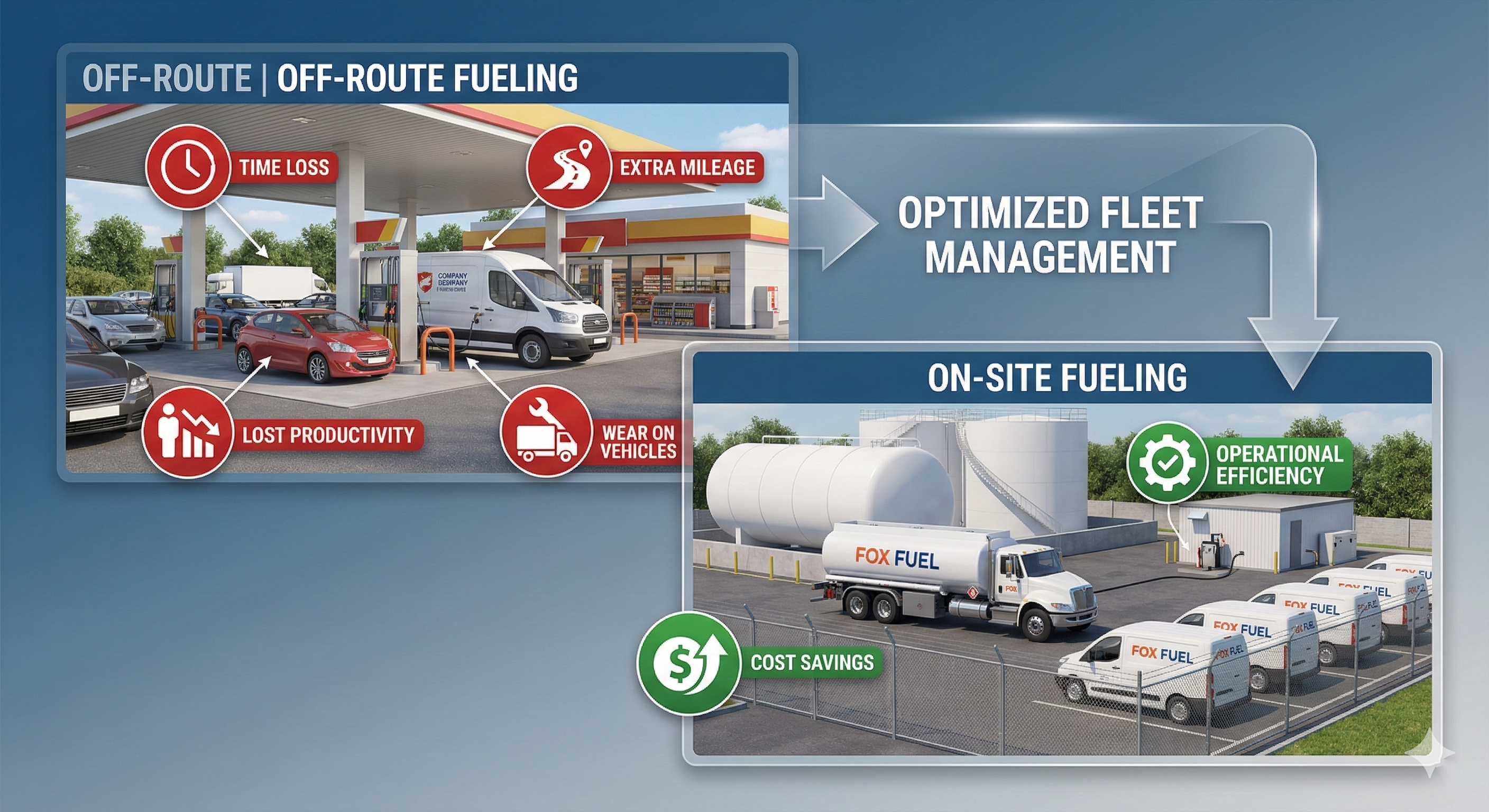

Ad-Hoc Purchasing Model

Definition: Fuel acquired reactively as needed, typically through retail stations, spot deliveries, or unscheduled bulk orders.

Operational Characteristics

- No delivery schedule or supply agreement

- Purchase decisions made when fuel runs low

- Pricing determined at time of purchase

- No dedicated account relationship

- Minimal operational coordination

Where This Model Works

- Low fuel consumption (under 500 gallons/month)

- No time-sensitive equipment dependencies

- Access to convenient retail fuel locations

- Staff available for fuel runs during business hours

- Tolerance for supply gaps or delays

Managed Fuel Program Model

Definition: Structured fuel supply relationship with scheduled deliveries, defined service standards, and operational coordination.

Operational Characteristics

- Recurring delivery schedule based on consumption patterns

- Dedicated account management and communication channel

- Defined response capability for unplanned needs

- Delivery documentation and compliance support

- Operational coordination (access, timing, equipment compatibility)

Where This Model Works

- Recurring or high-consequence fuel demand

- Equipment or fleets where downtime has material cost

- Operations requiring supply certainty and response capability

- Sites needing on-location fueling (construction, remote equipment)

- Facilities with backup generators requiring fuel readiness

Evaluation Framework

Use the following questions to assess alignment between your operational needs and fuel purchasing model.

Question 1: Operational Dependency

What happens if fuel is unavailable when needed?

Low Dependency Indicators

- Operations pause without significant cost

- Alternative fuel sources readily available

- Flexible timelines accommodate delays

- Staff can make retail fuel runs during normal operations

High Dependency Indicators

- Production stops or revenue halts

- Equipment sits idle with crew on payroll

- Generator failure creates facility shutdown risk

- Delivery vehicles miss scheduled routes

- Contract penalties apply for project delays

Evaluation: If fuel unavailability creates immediate, measurable operational impact, ad-hoc purchasing introduces unnecessary risk.

Question 2: Consumption Predictability

How predictable is your fuel consumption?

| Pattern Type | Characteristics |

|---|---|

| Unpredictable | Usage varies significantly week to week; no seasonal or operational patterns; single-event or occasional fuel needs |

| Predictable | Regular weekly or monthly fuel usage; seasonal patterns (winter heating, summer construction); equipment operates on consistent schedules; historical data shows consumption trends |

Evaluation: Predictable consumption enables scheduled delivery and automatic supply management. Unpredictable patterns may still benefit from managed programs if consequences of stockouts are high.

Cost Structure Analysis

Question 3: True Fuel Acquisition Costs

Many organizations evaluate fuel costs on per-gallon price alone. A complete cost assessment includes direct and indirect expenses.

Direct Costs

- Per-gallon fuel price

- Delivery fees (if applicable)

- Fuel taxes and compliance costs

Indirect Costs

- Staff time for fuel runs or ordering

- Equipment downtime waiting for fuel

- Lost productivity from supply gaps

- Emergency delivery premiums when stockouts occur

- Administrative overhead for multiple vendor relationships

Fuel purchasing model selection is an operational decision, not a procurement decision. The question is not "who offers the lowest price" but "which approach best serves operational requirements given fuel's role in business continuity."

Service and Response Requirements

Question 4: Unplanned Fuel Events

What response capability do you need for unplanned fuel events?

| Scenario | Ad-Hoc Model | Managed Program |

|---|---|---|

| Pre-storm generator fill | Call multiple vendors, hope for availability | Priority service for established accounts |

| Weekend equipment stockout | Retail stations only option | Emergency dispatch available 24/7 |

| Unexpected consumption spike | Scramble for spot delivery | Contact dedicated account manager |

| Delivery scheduling conflict | Start over with new vendor | Adjust within existing relationship |

Evaluation: If unplanned fuel events create operational risk or cost, a managed program provides defined response capability. Ad-hoc purchasing offers no service-level expectation.

Question 5: Documentation and Compliance

What documentation and compliance requirements apply?

Structured Documentation Needs

- Tax-exempt fuel tracking (municipalities, government)

- Environmental compliance records

- Fleet fuel allocation by vehicle or equipment

- Financial auditing requirements

- Off-road vs. on-road diesel separation

- DEF usage documentation for emissions compliance

Managed Program Advantage: Structured delivery programs provide delivery tickets with date, quantity, and product specification; consolidated invoicing for accounting; tax documentation for exempt organizations; and per-delivery records for compliance or allocation.

Operational Logistics Assessment

Question 6: Delivery Location and Method

Where and how does fuel need to be delivered?

| Delivery Need | Ad-Hoc Option | Managed Program |

|---|---|---|

| Fixed tank at facility | Spot bulk delivery | Scheduled delivery with monitoring |

| Fleet yard overnight fueling | Not typically available | Dedicated fleet fueling service |

| Construction site equipment | Retail fuel runs by operators | On-site mobile fueling to equipment |

| Generator at remote location | Emergency spot delivery only | Scheduled + emergency response |

| Multiple locations | Coordinate separately each time | Single vendor managing all sites |

Evaluation: Complex logistics benefit from vendor relationships that understand access, timing, and coordination requirements. Ad-hoc purchasing requires explaining logistics with every transaction.

Decision Matrix

Use this matrix to evaluate whether your current approach aligns with operational needs.

Strongly Indicates Ad-Hoc Model Is Sufficient

- Fuel consumption under 500 gallons per month

- No operational dependency on fuel timing

- Convenient retail fuel access

- No documentation or compliance requirements

- Simple logistics (single fixed location, no coordination)

- Staff available for fuel acquisition during operations

- Price is sole decision factor

- No emergency or unplanned fuel scenarios

If 6 or more factors apply: Ad-hoc purchasing likely serves operational needs adequately.

Strongly Indicates Managed Program Alignment

- Fuel consumption over 1,000 gallons per month

- Equipment or fleet downtime has measurable cost

- Operations require supply certainty and response capability

- Complex logistics (multiple sites, mobile equipment, specialized delivery)

- Documentation or compliance requirements exist

- Fuel acquisition consumes staff time or creates operational friction

- Emergency or storm-response fuel needs

- Vendor relationship and accountability provide operational value

If 6 or more factors apply: Managed program likely reduces operational risk and overhead.

Implementation Considerations

If Staying with Ad-Hoc Model

Optimize your current approach:

- Map fuel acquisition time and cost for visibility

- Identify backup vendors for supply gaps

- Document fuel costs including indirect expenses

- Establish process for emergency scenarios

If Transitioning to Managed Program

Preparation steps:

- Document Consumption Patterns: Historical monthly or weekly usage, seasonal variations, growth projections

- Map Delivery Logistics: Site access requirements, delivery timing preferences, equipment specifications, safety requirements

- Define Service Expectations: Required delivery frequency, emergency response needs, documentation requirements, communication preferences

- Evaluate Vendor Capabilities: Service area coverage, fleet capacity, account management model, customer references

- Establish Success Metrics: Supply reliability, cost performance, service quality, operational efficiency

Next Steps

If evaluation indicates potential managed program alignment:

- Quantify current fuel acquisition costs (direct + indirect)

- Map consumption patterns and delivery logistics

- Define service-level requirements

- Contact fuel suppliers serving your region to discuss managed program options

- Request references from customers with similar operational profiles

- Pilot test with highest-volume or most critical fuel application

- Assess operational and economic performance over defined period

About Fox Fuel Commercial Services

Fox Fuel provides managed fuel supply services to commercial, industrial, and institutional customers across Pennsylvania and New Jersey. Services include fleet fueling, bulk diesel delivery, generator fueling, on-site equipment fueling, and 24/7 emergency response.

Fox Fuel operates its own fleet from Pennsylvania, serving construction, fleet, healthcare, municipal, and industrial operations. Emergency dispatch is available 24/7/365 for established accounts.